Top Grade cone paper making chemicals - Sae Surface Sizing Agent – Tiankai

Top Grade cone paper making chemicals - Sae Surface Sizing Agent – Tiankai Detail:

The surface sizing agent is a styrene-acrylic ester high molecular polymer copolymerized with a variety of high molecular raw materials, which can be effectively combined with starch and endow the starch coating with good crosslinking strength and hydrophobic properties. It has the characteristics of small addition amount, low cost, good sizing effect and convenient use. This product is suitable for corrugated paper, cardboard paper, white board paper, and cow cardboard.

Technical index:

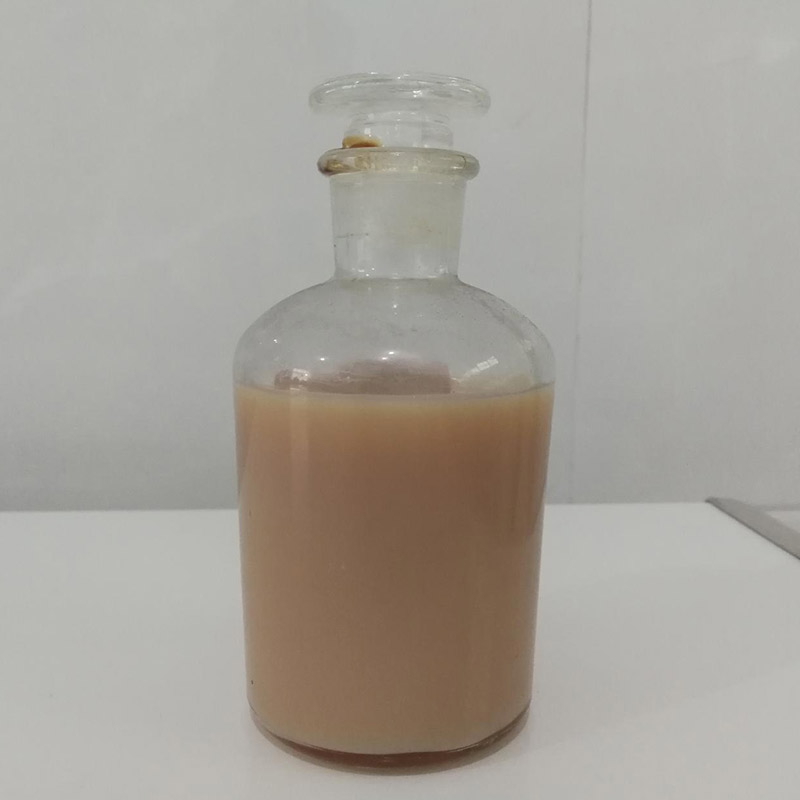

| Appearance | Light brown liquid |

| Solid content(%) | 30±1% |

| Ionic | Cationic |

| pH(25℃) | 3.0-5.0 |

| Viscosity, mPa.s (25℃) | ≤30mpa.s(25゜C) |

| Flammability | No |

| Solubility | Easily soluble in water at room temperature |

Performance characteristics:

1. Improve the high water resistance and ring compressive strength of corrugated paper, cardboard paper and other papers.

2. It can completely or partially replace the sizing agent in the pulp, purify the papermaking environment of the paper machine, and reduce the production cost.

3. It can greatly reduce the production of paper dust, improve printing adaptability and surface strength.

4. It has excellent mechanical stability and can be used on various types of sizing machines.

5. It has excellent mechanical stability, produces less bubbles during operation, and is more cost-effective than imported products.

Instructions:

1. Dosage: 1-2kg/ton paper.

2. When in use, when the gelatinized starch solution is cooled to below 75°C, slowly add the stock solution of this product into the batching tank under agitation, and stir evenly to sizing on the machine; or use a metering pump in the The starch is added continuously before the sizing machine.

Packaging and storage:

Packed in 200kg and 1000kg plastic buckets, stored in a cool place (4-30°C), avoid freezing and sun exposure.

Can be stored for 6 months.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Top Grade cone paper making chemicals - Sae Surface Sizing Agent – Tiankai, The product will supply to all over the world, such as: Singapore , Iran , Jordan , As operation principle is "be market-oriented , good faith as principle, win-win as objective", holding on "customer first, quality assurance, service first" as our purpose, dedicated to provide the original quality, create excellence service , we won the praise and trust in the industry of auto parts. In the future, We will provide quality product and excellent service in return to our customers , welcome any suggestions and feedback from all over the world.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!