Quots for bursting strength agent - Solid Surface Sizing Agent – Tiankai

Quots for bursting strength agent - Solid Surface Sizing Agent – Tiankai Detail:

This product is polymerized by a variety of cationic materials through a special process. It can be used for gelatinization together with starch. It does not require metering pumps and full-time sizing personnel,simple and convenient. It can not only reduce the amount of starch but also replace liquid surface sizing agent. Significantly reduce the cost of sizing.

This product is widely used in corrugated base paper, packaging paper, etc., with a small amount and obvious effect. It can effectively increase the stiffness, burst resistance, ring pressure strength, tensile strength and other physical indicators of the paper.

Main technical index

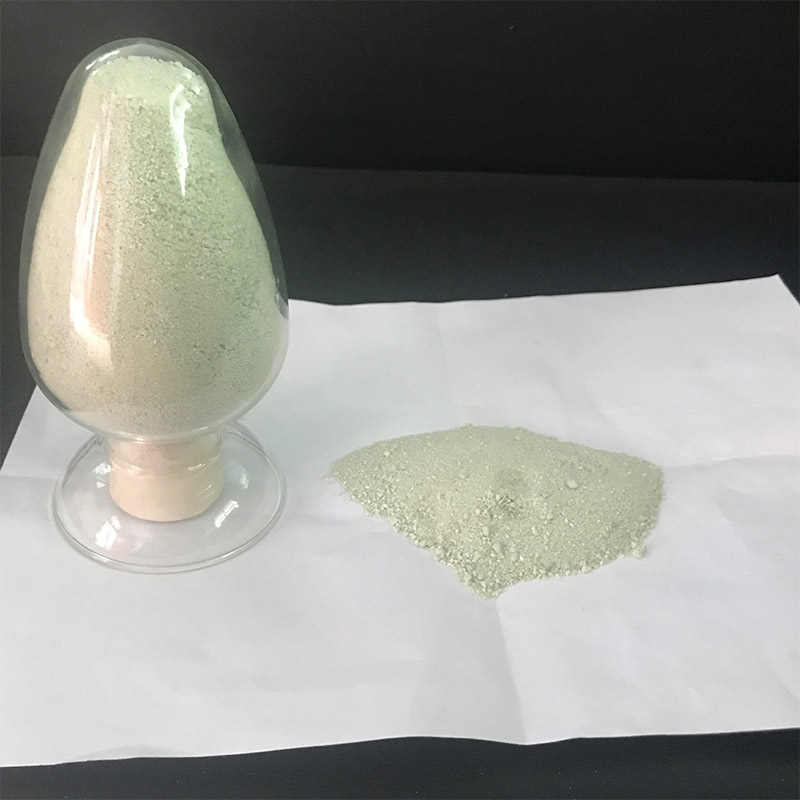

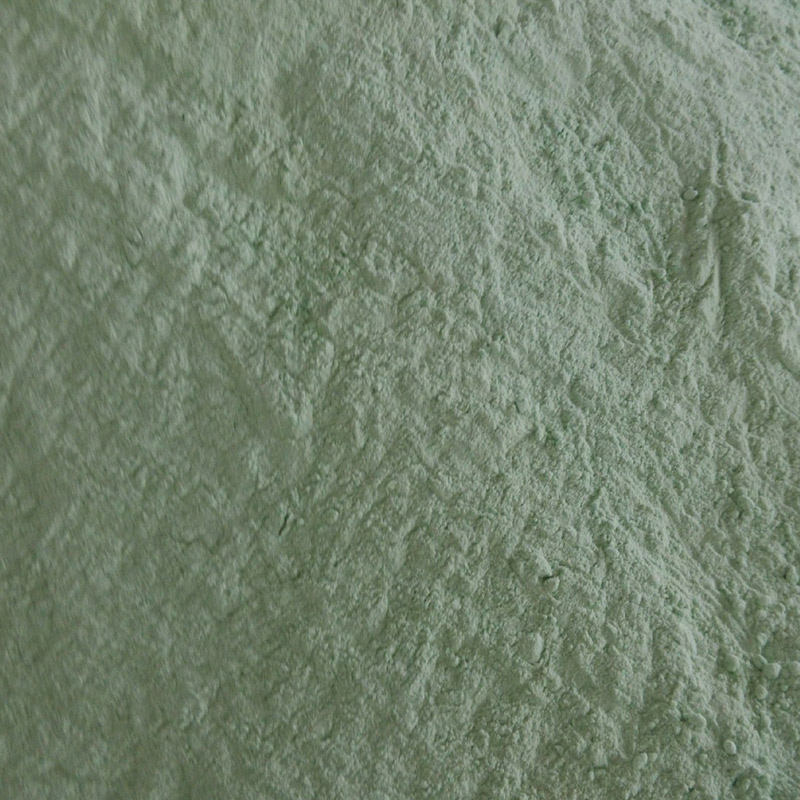

| Appearance | Light yellow to light Green Powder |

| PH | 2-5 |

| Content | 98% |

| Ionic type | Cationic |

| Particle size | 45-60 mesh |

| Solubility | easy soluble in water |

Use method:

1. Addition amount: The general amount is 15-20 kg per ton of paper, but it can also be determined according to the specific production situation.

2. Adding place: starch gelatinization tank.

3. Adding method: Operate according to the normal gelatinization process, first gelatinize the starch, after the starch is gelatinized, add the measured solid glue, stir for 20 minutes and then use it on the machine.

Product performance:

This product is added to the surface sizing starch, which can replace starch to reduce the amount of starch, increase the ring pressure strength of corrugated paper by 20-30% (increase 1.8-2 ring pressure index), and also improve the water resistance of corrugated paper, No need to add surface sizing agent to achieve 2-5 minutes of water resistance.

Packaging and storage:

25 kg/bag. The storage period is 12 months in a ventilated and dry place.

Product detail pictures:

Related Product Guide:

Being supported by an advanced and professional IT team, we could offer technical support on pre-sales & after-sales service for Quots for bursting strength agent - Solid Surface Sizing Agent – Tiankai, The product will supply to all over the world, such as: Iceland , Swiss , Johannesburg , because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

A good manufacturers, we have cooperated twice, good quality and good service attitude.