One of Hottest for polyacrylamide cationic pulp chemicals-paper dry strength agent - Polymer Akd Emulsifier – Tiankai

One of Hottest for polyacrylamide cationic pulp chemicals-paper dry strength agent - Polymer Akd Emulsifier – Tiankai Detail:

Technical index

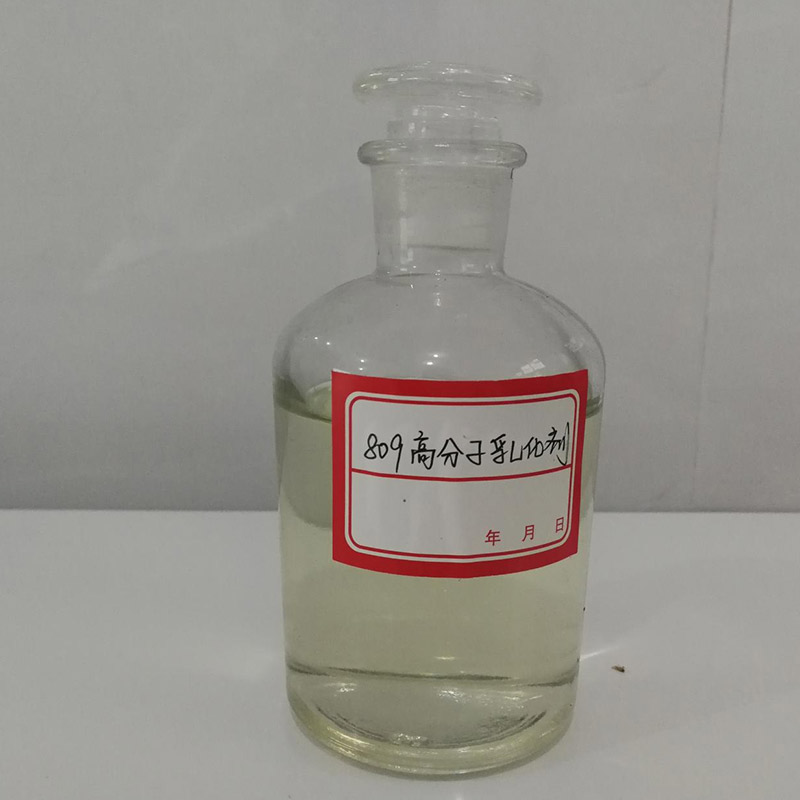

| Appearance | Colorless to light yellow transparent liquid |

| Solid content(%) | 40±1 |

| PH value(%) | 3-7 |

| Viscosity (mpa.s(25゜C) | 5000-12000 |

Performance characteristics

This product is directly added to the intermediate synthesis process, or added in a certain proportion in the emulsion. It can be added to the heavier anionic waste papermaking system as a slurry potential balance agent, which has the dual effect of sizing synergism and ripening. It can improve the stability of neutral glue, limit the hydrolysis and migration tendency of AKD, protect AKD latex, accelerate the maturation of AKD, and the dosage is recommended to be adjusted by yourself. It can also be used as antistatic agent for A4 paper, retention and enhancement dispersant And color paper fixing agent

Use method

1. Add 10kg-30kg of JH-5020A polymer emulsifier per ton of AKD emulsion.

2. The more the polymer emulsifier is added, the better the sizing effect will be in the later stage. However, if the amount is too high, it may cause local precipitation of the AKD emulsion; adding this product can prolong the storage time of the AKD emulsion.

Packag & storage

This product is packed in a 1000kg plastic bucket; stored in a cool place, avoid freezing and sunlight. The storage period is 12 months.

Product detail pictures:

Related Product Guide:

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for One of Hottest for polyacrylamide cationic pulp chemicals-paper dry strength agent - Polymer Akd Emulsifier – Tiankai, The product will supply to all over the world, such as: UK , US , Belgium , They're durable modeling and promoting effectively all over the world. Under no circumstances disappearing major functions in a quick time, it's a should for you of excellent good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the company make a terrific efforts to expand its international trade, raise its company profit and raise its export scale. We're confident that we are going to possess a vibrant prospect and to be distributed all over the world within the years to come.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!