Factory Price akd emulsion in paper making - Solid Surface Sizing Agent – Tiankai

Factory Price akd emulsion in paper making - Solid Surface Sizing Agent – Tiankai Detail:

This product is polymerized by a variety of cationic materials through a special process. It can be used for gelatinization together with starch. It does not require metering pumps and full-time sizing personnel,simple and convenient. It can not only reduce the amount of starch but also replace liquid surface sizing agent. Significantly reduce the cost of sizing.

This product is widely used in corrugated base paper, packaging paper, etc., with a small amount and obvious effect. It can effectively increase the stiffness, burst resistance, ring pressure strength, tensile strength and other physical indicators of the paper.

Main technical index

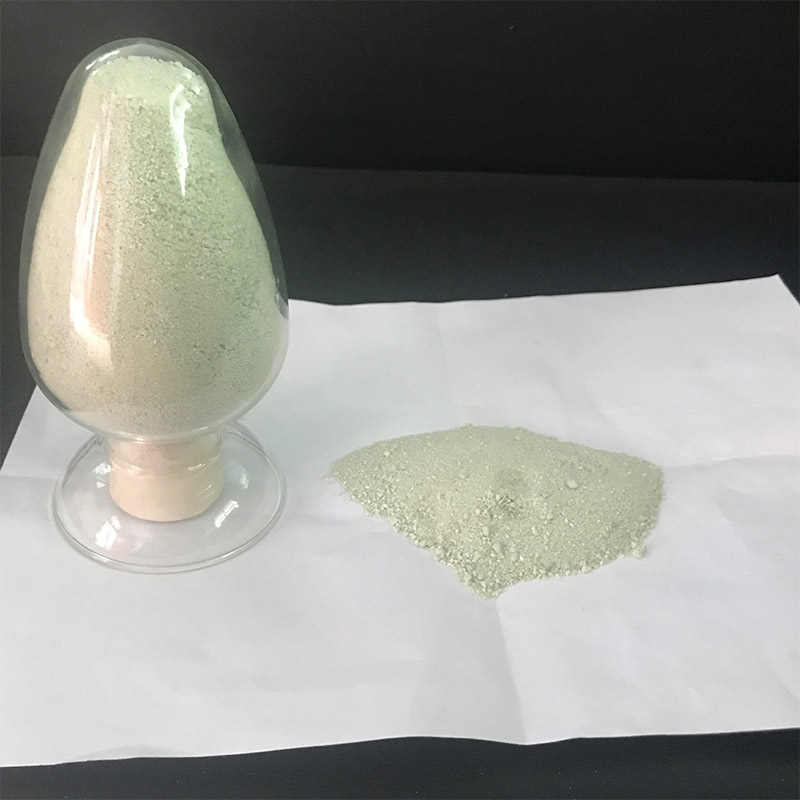

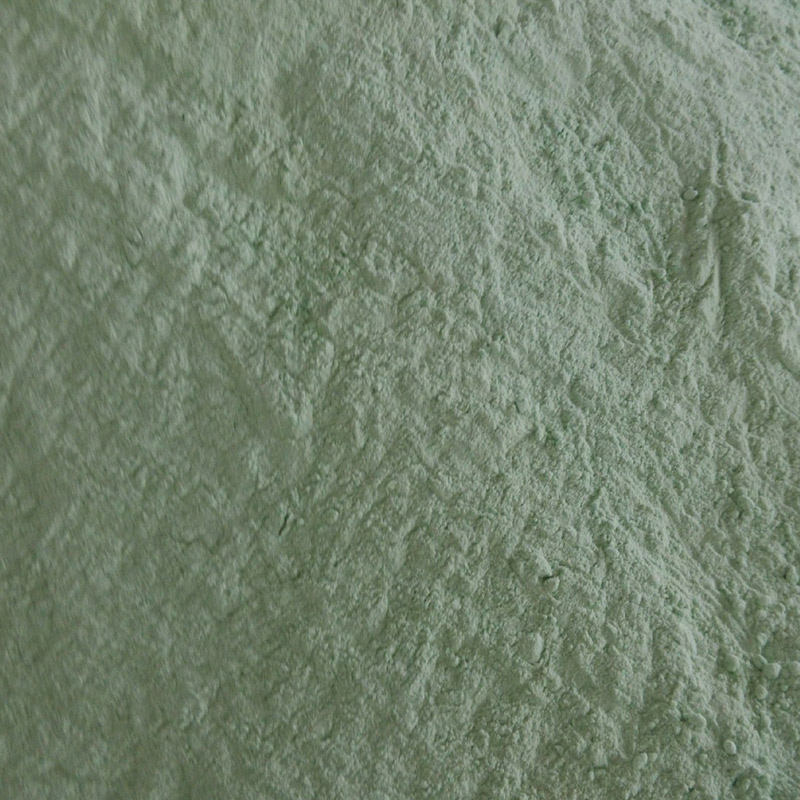

| Appearance | Light yellow to light Green Powder |

| PH | 2-5 |

| Content | 98% |

| Ionic type | Cationic |

| Particle size | 45-60 mesh |

| Solubility | easy soluble in water |

Use method:

1. Addition amount: The general amount is 15-20 kg per ton of paper, but it can also be determined according to the specific production situation.

2. Adding place: starch gelatinization tank.

3. Adding method: Operate according to the normal gelatinization process, first gelatinize the starch, after the starch is gelatinized, add the measured solid glue, stir for 20 minutes and then use it on the machine.

Product performance:

This product is added to the surface sizing starch, which can replace starch to reduce the amount of starch, increase the ring pressure strength of corrugated paper by 20-30% (increase 1.8-2 ring pressure index), and also improve the water resistance of corrugated paper, No need to add surface sizing agent to achieve 2-5 minutes of water resistance.

Packaging and storage:

25 kg/bag. The storage period is 12 months in a ventilated and dry place.

Product detail pictures:

Related Product Guide:

As a way to ideal meet up with client's desires, all of our operations are strictly performed in line with our motto "High Top quality, Competitive Cost, Fast Service" for Factory Price akd emulsion in paper making - Solid Surface Sizing Agent – Tiankai, The product will supply to all over the world, such as: Chile , Atlanta , Cape Town , By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.